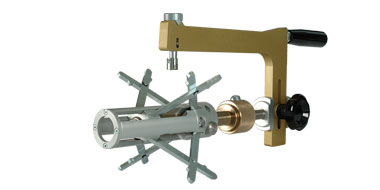

A dip oven is usually used for manual or automatic crane systems in which dip heat treatment is required during the finishing process.

AABO’s dip ovens are available for use at several temperature levels. This means that we offer them in a variety of different insulation layers and constructions.

- 0 -100 °C: 100 mm, two layers of mineral wool

- 100 – 250 °C: 200 mm, three layers of mineral wool

- 250 – 550 °C: 300 mm, one layer of brand batch + three layers of mineral wool

AABO’s dip ovens are designed as a ‘floating’ internal core, suspended using a minimum of contact points to the bearing external construction. This minimises the development of a heat bridge.

AABO’s dip ovens are all based on the convection principle which ensures optimum energy utilisation. Heat is injected into the lower section of the oven chamber either through air ducts in the floor or in the walls. The air is recirculated from the top of the oven chamber across a heating unit. This ensures correct and optimum thermal air distribution as well as uniform heat transmission to the production items.

AABO’s dip ovens can be heated using:

- Gas

- Oil

- Electricity

AABO’s dip ovens are available with:

- Direct heating

- Indirect heating

AABO’s dip ovens are available as:

- Door ovens into which production items are transported through sliding doors located at the top of the oven chamber. The doors are available either as manually operated or fully automated doors