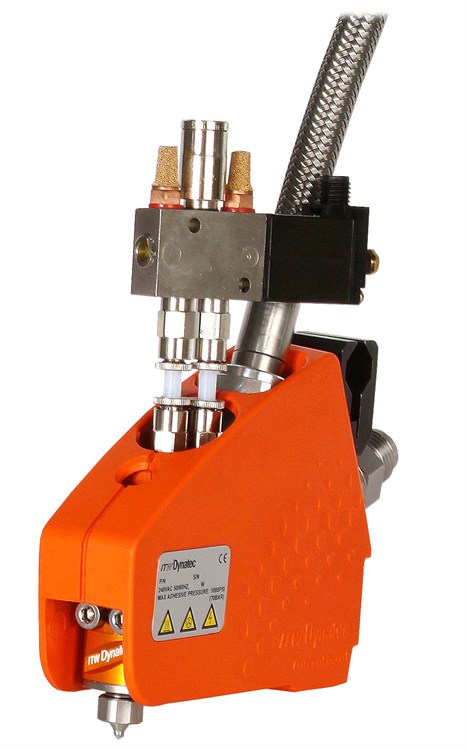

Overview

- Integrated needle and self-cleaning nozzle virtually eliminate adhesive stringing. (Micro Optima module)

- Dual-port pivoting modules simplify set-up by providing simple adjustment of bead placement.

- Adjustable needle stroke sets adhesive flow for extreme accuracy. (Micro Adjustable module)

- On/Off cycle speeds of 3.5 milliseconds is ideal for high-speed applications.

- Cover increases safety and promotes energy efficiency.

- Industry exclusive built-in filter captures debris and minimizes nozzle clogging.

Features

- Compact size provides for easy installation into packaging machinery.

- Insulated thermoplastic cover increases safety by reducing operator exposure to hot surfaces.

- Enhanced built-in filter captures debris and reduces downtime due to clogged nozzles.

The Dynatec Difference

The BF MicroBead applicator module is designed to operate as an air open/air close system that does not rely on a spring to close the orifice during operation. The result is both cleaner cutoffs and superior operation over a longer operating lifespan. While this feature may be optional on competitive modules, only ITW Dynatec offers this feature standard on the BF MicroBead adhesive applicator.